Aircraft Structures - An aircraft is a device that is or is used for flying in the air. The main categories of aircraft are airplanes, rotorcraft, gliders and light air vehicles. [Figure 1] Each of these can be further divided according to the main characteristics of aircraft, such as airships and balloons. Both are lighter than airplanes, but have unique characteristics and operate differently.

This article focuses on aircraft; Specifically fuselages, arms, nacelles, armor, armor, airfoil surfaces and undercarriage. Also included are the various accessories and controllers associated with these structures. Note that helicopter rotors are actually part of the airframe, as they are rotating wings. On the other hand, the engine propeller and rotating airfoils on an aircraft are not considered part of the airframe.

Aircraft Structures

The most common aircraft is a fixed-wing aircraft. As the name suggests, the wings on this type of aircraft are attached to the aircraft and are not intended to move independently in a lift-generating manner. One, two or three sets of wings were all used successfully. (Figure 2) Rotary wing aircraft such as helicopters are also widespread.

Fatigue Of Aircraft Structures

This section discusses features and maintenance aspects common to the fixed-wing and rotary-wing aircraft categories. In addition, in some cases the explanations focus on information specific to one or the other. Gliders are very similar to fixed-wing aircraft. Unless otherwise stated, the maintenance procedures described for fixed-wing aircraft also apply to gliders. The same goes for lighter-than-air aircraft.

The airframe of a fixed-wing aircraft consists of five main components: fuselage, wings, stabilizers, flight control surfaces and landing gear. (Figure 3) The airframe of a helicopter consists of a fuselage, main rotor and associated gearbox, tail rotor (one main rotor in helicopters) and landing gear.

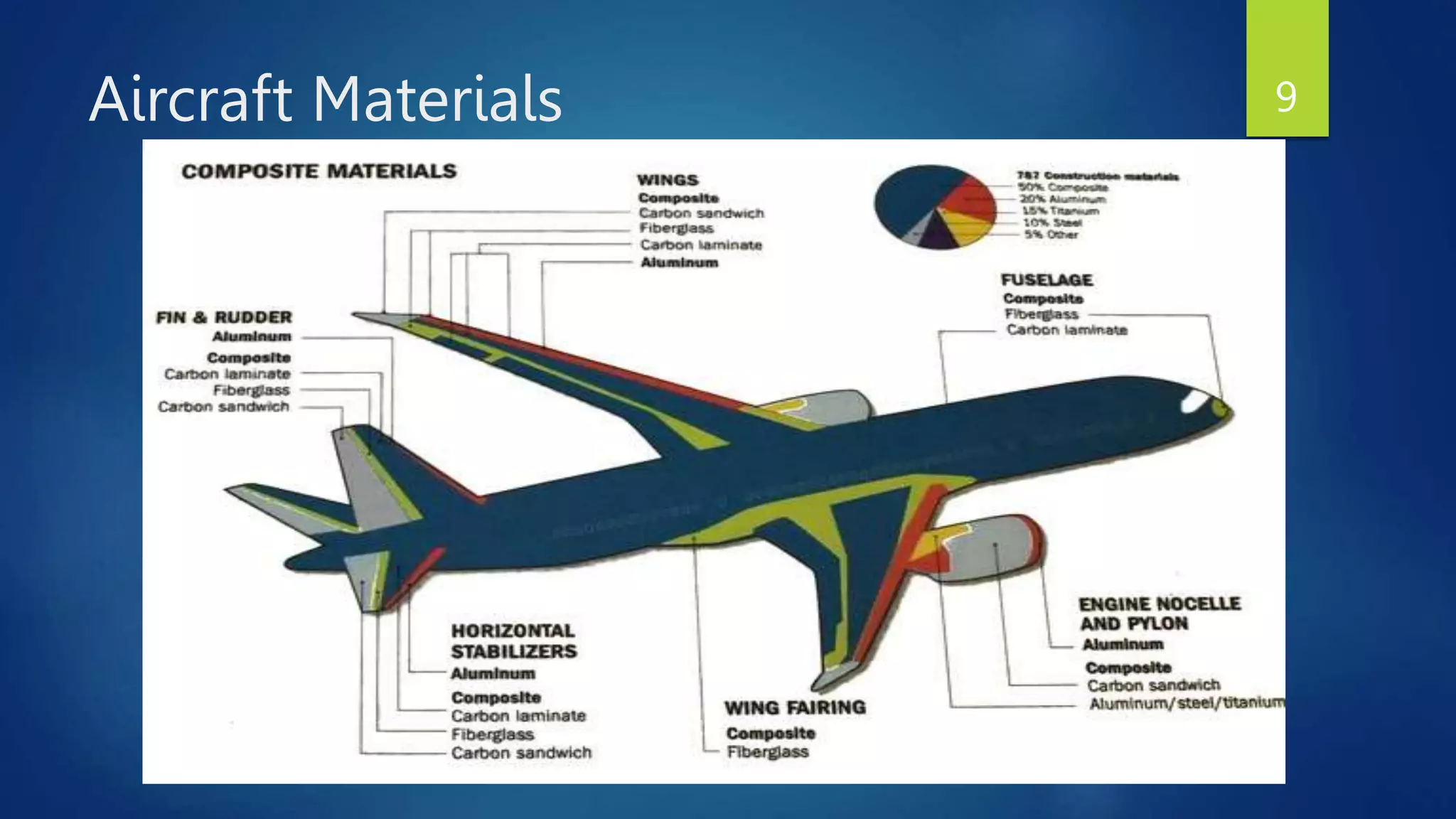

The structural elements of the airframe are made of different materials. The first airplanes were mostly made of wood. This was followed by steel pipes and the most common material, aluminum. Many new certified aircraft are made of composite materials such as carbon fiber. Airframe structural elements include chords, flaps, ribs, bulkheads and more. The main structural member in the wing is called the wing spar.

Aircraft skin can be made from a variety of materials, from pressed fabric to plastic, aluminum or composites. Underneath the fairing and attached to the structural fuselage are several components that support the operation of the airframe. The entire framework and components are interconnected with rivets, screws, bolts and other fasteners. Welding, gluing and special joining methods are also used.

Mooc: Introduction To Aerospace Structures And Materials

History of Aircraft Structures Major Structural Loads Fixed Wing Aircraft Wing Employment Primary Flight Control Decks and Dual Purpose Flight Control Areas Secondary or Auxiliary Control Decks Other Wing Features Undercarriage Maintenance of Airport Helicopter Structures Secondary Aeronautical Engineering Design and Knowledge Electrical, Aeronautical and Mechanical Cabin qualification and certification of systems. Validation features include static strength and stiffness, fatigue life, crack propagation and tolerance calculations.

He also has extensive experience in electrical, structural and systems maintenance engineering support and troubleshooting, as well as airframe maintenance interpretation, verification and validation.

The entire numerical process from design to stress calculation is supported by the use of state-of-the-art software: CATIA V5 (design) and NASTRAN/PATRAN (stress) with associated product life cycle management (windchill) in-house or externally CATIA CADAM Drafting (CCD) V4, CATIA V4.

EFW was responsible for the design, approval and production of the upper part of the A300-600ST "Beluga" shells and frames and some other parts in this area. This project is the first to establish a basic knowledge of the design and certification of early aircraft.

Buy Aircraft Structures Book Online At Low Prices In India

Package-to-cargo programs are key functions of EFW Engineering. EFW is responsible for adaptation engineering and conversion support for A310/A300-600 P2F conversions, provided complete electrical design for the previous A320P2F conversion project and actually integrated electrical functional design and installation design and floor panel design for the A330P2F program.

The A310MRTT was assigned several missions to the German and Canadian air forces. Conversion to a multi-purpose transport version and integration of a set of 6 aircraft fuel tanks is supported. Engineering was responsible for the integrated design of the antenna installation, which included new and updated avionics systems and a unique camera system to support in-flight refueling operations.

In addition, EFW Engineering was responsible for the static strength accuracy of most A340-500 and A340-600 forward wing shells and frames.

EFW serves as a risk-sharing partner for the A380 and A350 floor panels and lower baggage compartment covers.

Largest Composite Aircraft Structure Optimised With Smart Software

For the EC 135 helicopter, a modification of the airframe was carried out, and the rail and seabed, as well as the cover plate, were developed as an activity outside the aviation industry. Type – Pratt Truss – Warren Truss – Monocoque – Semi-Monocoque Basic Structure Member Terms Wing Structure Encapsulation Structure Power Plant – Wing Girder – Fuselage Girder Undercarriage Structure

4 propeller landing gear Wing Left ailerons Fuselage Nacelle bulge Right ailerons Horizontal stabilizer Vertical stabilizer Rudder Elevator

It usually consists of two or more parts and contains accessories and other equipment.

8 Truss Type Most early aircraft used this method with wood and wire trusses and this type of structure is still used in many light aircraft with welded steel tube trusses. The supporting frame of the hull is assembled with members that form a rigid frame, e.g. Beams, rods, pipes, etc... The main supporting members are 4 long. There are two types of roof construction. - PRATT TRUST - Warren Trust

University Funded To Investigate Lightweight Composite Aircraft Structures

Force transmission to all structures Reduce the size of meshes that can withstand tension + compression More space, strength, stiffness Better optimization.

12 MONOCOQUE In this method, the exterior of the hull is also the main structure. This distinctive early design was built with carved wooden planks. A later version of this structure uses fiberglass fabric impregnated with polyester or epoxy resin instead of pine wood.

13 Semi-monocoque This is the preferred method for producing an all-aluminum hull. First, a set of frames in the form of a cross-section of the fuselage is held on a rigid stand or template. These frames are then joined by lightweight longitudinal members called stringers. These, however, are covered with a panel made of aluminum skin, fixed with reference or special glue. Most modern large aircraft are built using this method, but many large parts made this way are then joined together with fasteners to form the entire fuselage.

We collect and share user data with processors for the operation of this website. To use this website, you must agree to our privacy policy, including our cookie policy.

Buy Composite Materials For Aircraft Structures (aiaa Education) Book Online At Low Prices In India

Aircraft structures pdf, aircraft financing structures, aircraft structures technician, aircraft structures book, aircraft structures mechanic, aircraft structures mechanic jobs, aircraft composites structures, aircraft composite structures, aircraft structures jobs, aircraft structures engineer, aircraft structures technician salary, miami aircraft structures

0 Comments