Aircraft Strut - The oil pump is a pneumatic air-oil hydraulic absorber used in the landing gear of large aircraft and many small aircraft.

It is undesirable to bounce the aircraft on exit, which may result in loss of control.

Aircraft Strut

And landing gear should not be attached to this tdcy. A steel coil spring adds energy from the landing impact and emits it, while an oil strut instead absorbs that energy, reducing rebound.

Figure 4 170. Simple Shock Strut

As the pulse is compressed, the spring rate increases significantly as the air is compressed. The viscosity of the oil reduces to kickbacks.

The original design of the oleo-pneumatic shock absorbing strut was proven in 1915 by the British manufacturing company Vickers Armstrong.

It was derived from a Vickers mechanical engine, which controlled the recirculation of oil by forcing it through precise holes. Vickers oil struts were first applied to aircraft by the French aircraft company Aviation Breguet.

The design has been proven feasible and is widely used in the aerospace industry for specific runs, simply being attached to the "Oleo unit" or to the foot of the undercarriage.

A320 Nose Strut Was Over Serviced At The Last Station And Bags Miss Loaded In The Rear

However, the initial Vickers design had air over oil, an arrangement that caused no problems until the introduction of retractable landing gear in the mid-1930s. Instructor Peter Thornhill developed a new strut undercarriage from the builder that uses a free-floating piston using not only a lighter composition, but also eliminates the disadvantage of using an oil and air mixture, allowing the entire support to be inverted and operated at an angle.

The oleo-pneumatic technology was later adopted by the manufacturer to produce several other products, including hydraulic bumpers and shock absorbers.

In 1926, the Cleveland Pneumatic Tool Company designed and released its oil strut, one of the first designed specifically for use in airplanes. The company then marketed the product as an aeronaut widely sold in the United States within a decade.

In the twenty-first century, a wide variety of different shock-absorbing devices were in use, but common principles were typically used, despite significant differences in size, weight, and other performance characteristics.

Aircraft Landing Gear Support

In addition, improvements were made in the technique of leaving oil sutures. In 1954, hydropneumatic suspension was introduced, using the same principle of compressed gas (nitrog) and non-compressed liquid; in this application a Guinea-driv pump is used to pressurize the hydraulic fluid.

In 2012, it was proposed that the vibration dampening properties of oil blends could be improved by using semi-active controls to adjust the viscosity of the fluid.

According to Gineering360, as of 2019, the oleo-pneumatic strut has become the most common type of shock absorber in modern aircraft.

In particular, oil struts are widely used in the largest commercial aircraft such as Antonius An-124 Ruslan; as they say, it provides the ability to land in rough terrain, carrying loads up to 150 thousand tons. This design also protects against the effects of taxing the airframe, providing a higher level of comfort for both passengers and crew.

Freighter Aircraft Departs With Tail Strut Attached Due To Incomplete Checklist Execution

For non-flight purposes, the Quadro range of powered scooters uses oil struts, which are claimed to provide the appropriate lean speed characteristics.

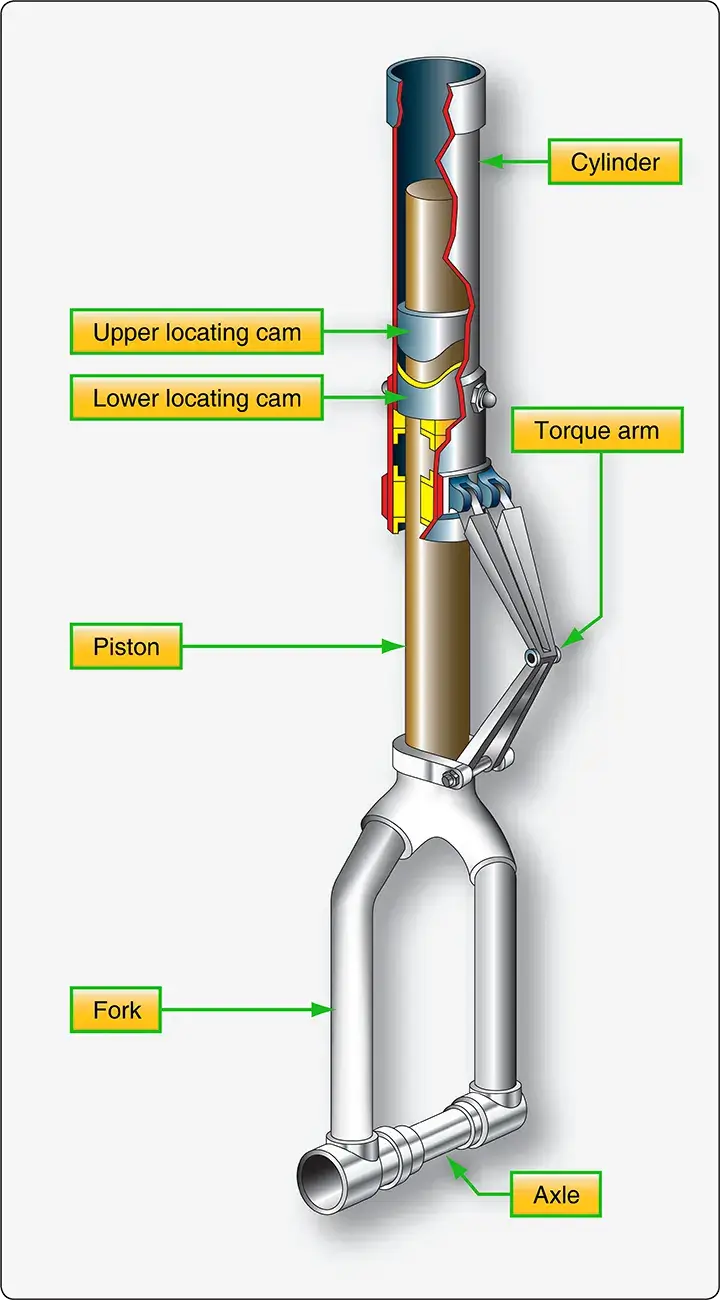

An oil pump consists of an inner metal tube or piston that adheres to the axle of the wheel and is attached up and down to an outer metal tube or cylinder body. The space in the strut and piston is filled with gas (usually nitrous, sometimes air - especially in light aircraft) and oil (usually hydraulic fluid) and is connected to the two parts by a small, precisely calculated hole. .

When the aircraft is stationary on the ground, its weight is supported by a cylinder of compressed gas.

This action compresses the gas, which acts as a spring, and forces the oil through the opening, which becomes the damper. Some people use a pointed rod to change the size of the hole as the piston moves, making it more resistant as the compression stroke increases. Additionally, the check valve is sometimes used to clarify with additional holes to dampen compression less than rebound. Oil reserves absorb and disperse forces, converting some of the accumulated kinetic energy into thermal energy.

Troubleshooting Of Landing Gear Systems

Pneumatic systems such as Oleo Strut generally have a long operating life and are not usually of complicated construction for maintenance purposes.

Nitrogen is often used in gas rather than air, which is less likely to cause corrosion. The various parts of the support are sealed with o-rings or similar elastic seals, and a scraper ring is used to prevent dust and sand from sticking to the piston and damaging it. No matter how hard we all try, not every approach is perfect. . But because of the baggage allowance, even an incomplete boarding will not disrupt your flight.

There are 4 main types of access support equipment and they are all designed to help take the "boost" out of your port. Here's how they work.

The original type of port gear was rigid. The idea was simple: to group the wheels to the body. It was an important question; The hard port meant that powerful impact loads were transferred directly to the fuselage. And the pilot and passengers certainly felt it.

Ups A332f Main Ldg Strut

Shortly thereafter, mechanical engineers began installing inflatable tires on aircraft, and air cushioned the impact of the load. Although it is not a perfect solution, it certainly helps.

Although you don't see these often these days, you can still find hard feet on the ramp. Almost all helicopters use them in the form of a metal skil attached to the helicopter.

One of the most common systems in general aviation aircraft is the spring steel strut. If you've ever flown a Cessna, you know what it's like. These planes use strong, flexible materials, such as steel, aluminum or composites, to help carry the impact port.

When your plane hits the ground, the springs flex upward, dispersing the shock load and transferring it to your fuselage at a speed that doesn't turn your plane. Steel is popular because it is mechanically simple, typically lightweight, and requires little or no maintenance. Also, if you're like me when I learned to run away, you know that it can really take a beating.

Strut Of Plane Hi Res Stock Photography And Images

Bungee cords are commonly found on the tailwheel and overboard aircraft. One of the most popular models that you've probably seen is the Piper Cub.

Bungee cords are just that - a series of elastic cords flexibly wrapped between the fuselage and the gear system allows the gear to transfer an impact load onto the plane, certainly harmless to the plane. While some aircraft use a ring-type rubber cushion, most use many individual plates of elastic material to disperse the impact, as shown in the image below.

The last type of strut is the only true shock absorber. A twisted shock, often called an oil or air/oil network, uses a combination of nitrogen (or sometimes compressed air) and hydraulic fluid to absorb and disperse shock loads into the port. You can find them on some of the smaller planes like the Piper Cherokee, but you'll usually find them on larger planes like jet skis and airplanes.

The shocks and feet use two cylindrical telescopes, both closed at the outer ends. The top cylinder is attached to the aircraft, and the bottom cylinder is connected to the port gear. The lower cylinder, typically called the piston, can also slide freely out of the upper cylinder.

Preflight Descriptions: More Than Merely 'check,' Part 2

If you look at a cross section of two cylinders, there is almost always a lower cylinder filled with hydraulic fluid, an upper cylinder filled with nitrogen, and a small hole called the junction of the two holes.

When they land, the pressure of the wheels on the ground carries a supply of hydraulic fluid upwards, and in the upper layer is filled with nitrogen. As the moisture passes through the hole (very quickly, along the way) it generates heat. And essentially, the kinetic energy of the moving hydraulic fluid is converted to thermal energy and the impact of your descent is absorbed.

You can see the oil acting twisted as you observe the flat ground. A perfect example was the Atlantic Virgin 747, which had landed on one of its main runways. The rest of the three main ships took support and pulled the port, and you can see that they stuck to the port.

We're all trying to land perfect ports, but even when we have a free day, it's good to know that support arms are there to help us land properly.

Aerial Mid Air View Of The Wing Strut Of A Piper Pa18 Super Cub Light Aircraft Stock Photo

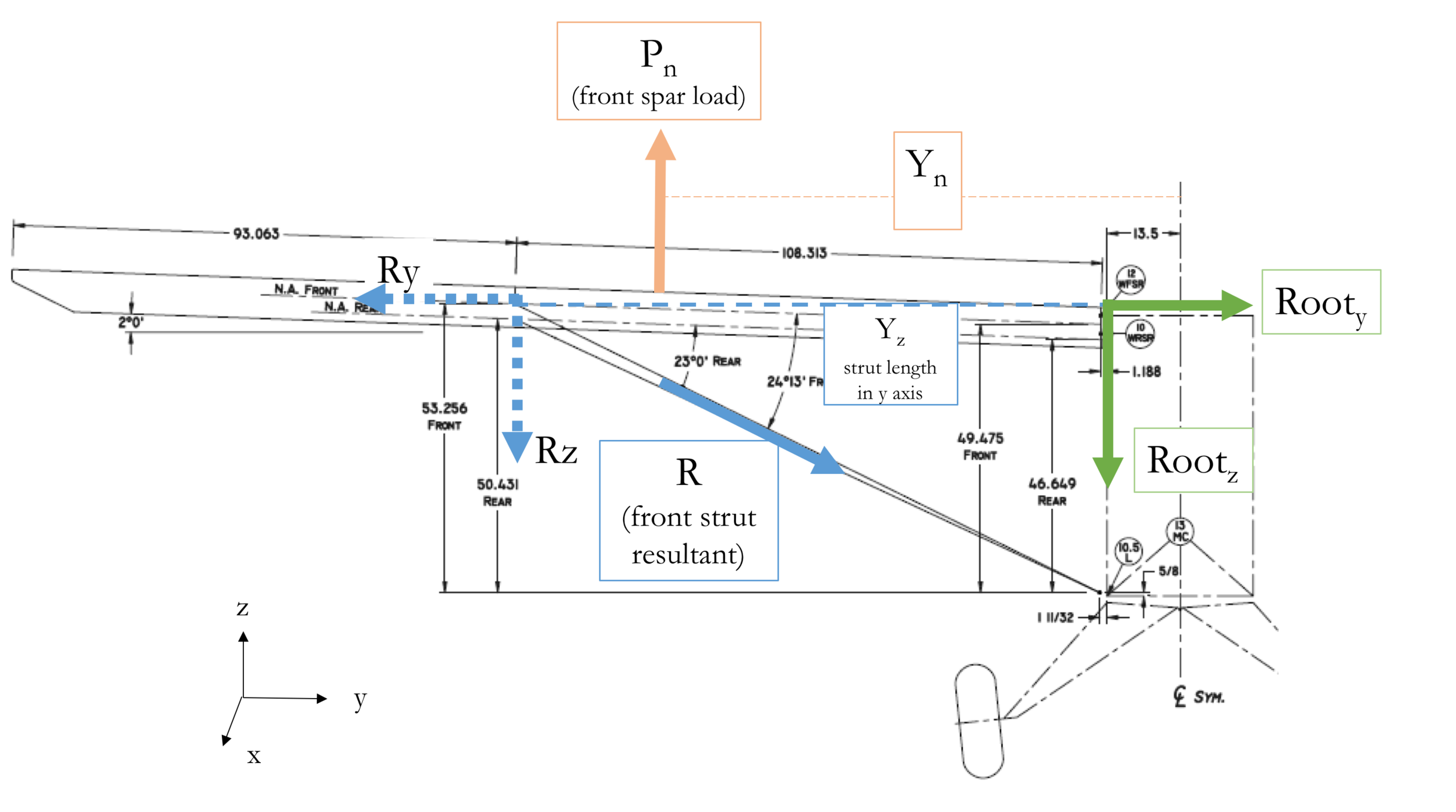

Colin is the organizer and pilot of life. He was a flight instructor at the University of North Dakota, a pilot on the Crj-200 airliner, and oversaw the development of several commercial and military training systems. You can reach him at colin@. The Arctic Tem lifting strut design - a known point of failure in wing loading - must be improved to support FAA load certification conditions.

Slotted strut, galvanized strut, power strut, strut repair, strut hangers, aircraft strut servicing tool, strut replacement, aircraft strut pump, strut this, aircraft shock strut, fiberglass strut, aircraft strut pump for sale

0 Comments